Alexyl

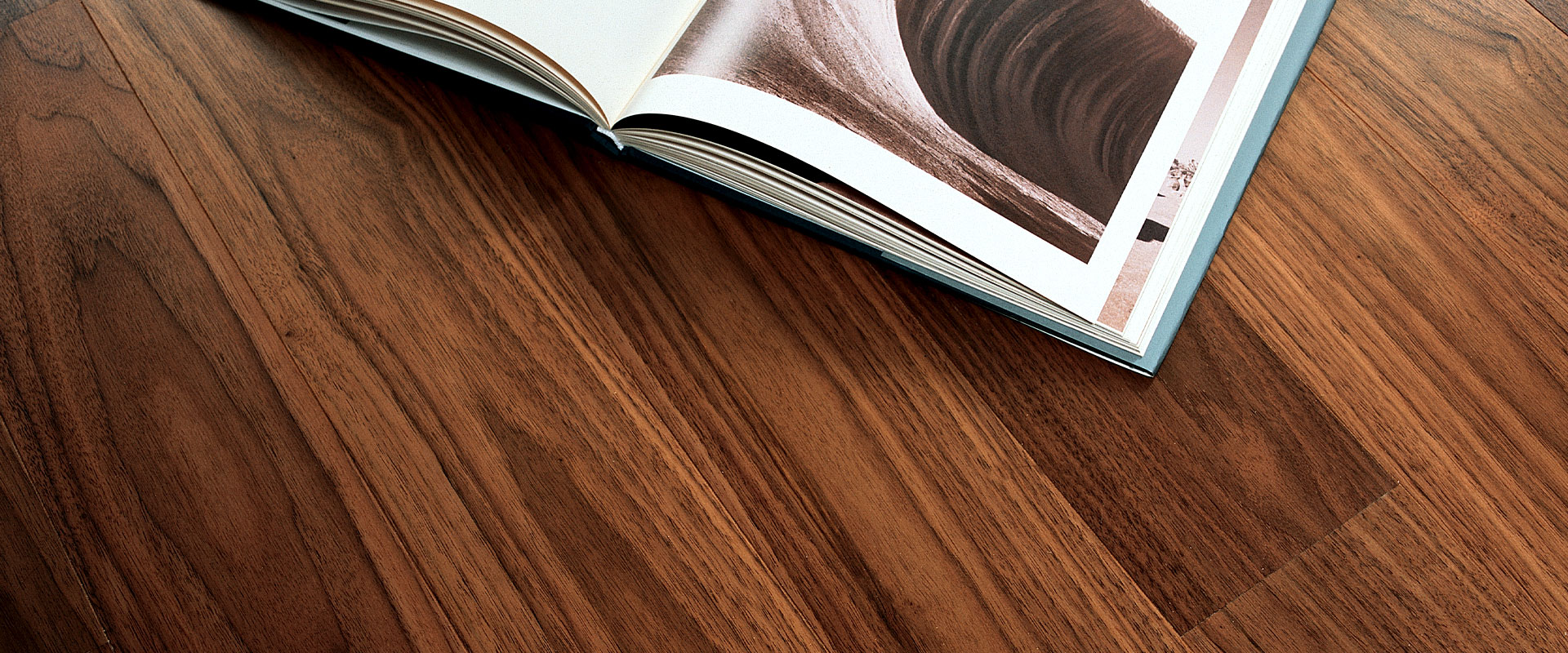

Absolutely Stunning

OUR HISTORY IN BRIEF!!!

Alexyl is established. The company has its owned facilities 10 km outside the city of Thessaloniki and a closed indoor storage area of 10,000 m2 for the distribution of timber products. The company’s scope is to import logs from Europe and Africa and to produce wooden floors from various kinds of wood.

Alexyl imports the well known MDF that brings a real breakthrough in the domain of furniture.

The company builds new owned facilities on the ΝΑΤΟ Avenue in Aspropyrgos, Attica, and extends its activities of supplying MDF, timber raw materials and wooden floors in Southern Greece.

The company opens a new store in Thessaloniki, which is located at 70-72 Georgiou Papandreou street, where there is a showroom of wood products, along with innovative solutions for floors, panelling and ceiling linings. The new products -wood and other products- offer unique architectural and decorative high aesthetic solutions, for indoor and outdoor spaces of residences and working areas. Furthermore are presented, for the first time in Greece, the prefinished multi-layered solid floors, which are widely known as engineering wood floors.

In the middle of the year opens in Athens, and more particularly in the suburb of Glyfada, one of the largest showrooms in Europe, of an area of 1,000 m2. In this area are exposed wooden floors that combine advanced technology and high aesthetics. Products which consist the most modern solutions that technical evolution has to offer as well as the most innovative proposals regarding their design, giving new dimensions to the selection of a wooden floor.

today

Alexyl continues its dynamic course, offering new products and technologies that are constantly updated and readjusted, so that they can fully meet the modern needs and requirements. With these criteria, Alexyl imported to the Greek market the «glass doors, wooden doors and walk-in closet systems, as well as safety doors and wall coverings.»

Why choose ALEXYL S.A.

QUALITY

Having an increased environmental awareness and sensitivity, an environmentally-friendly policy is applied regarding forest resources, which consists a real innovation in the particular domain.

As a first result of this, the FSC and PEFC certifications, that regard the production process, were granted, after the inspection, monitoring and control of the entire production process, from the cutting of trees to the final product.

This is a very important achievement, as it is required to use certified, renewable sources, an activity in which our company is actively involved.

Until today, the range of wood products for which this particular certifying procedure is applied is not a great one, since the so-called tropical species are not included (for the time being only jatoba is included). On the contrary, the European species (oak tree, beechtree, maple, European and Canadian maple), are certified and their products are characterized by a wide range of colours, in various sizes and finishes that can satisfy every aesthetic requirement.

PROTECTION & ABILITY TO SUPPORT THE ENVIRONMENT

Having an increased environmental awareness and sensitivity, our company applies an environmentally-friendly policy regarding forest resources, which consists a real innovation in the particular domain.

As a first result of this, the FSC and PEFC certifications, that regard the production process, were granted, after the inspection, monitoring and control of the entire production process, from the cutting of trees to the final product.

This is a very important achievement, as it is required to use certified, renewable sources, an activity in which our company is actively involved.

Until today, the range of wood products for which this particular certifying procedure is applied is not a great one, as the so-called tropical species are not included (for the time being only jatoba is included). On the contrary, the European species (oak tree, beechtree, maple, European and Canadian maple), are certified and their products are characterized by a wide range of colours, in various sizes and finishes that can satisfy every aesthetic requirement.

Our collections represent a real aesthetic and technological breakthrough and consist of products the wood of which has undergone thermal processing only, offering a huge variety of colours, without the use of any chemicals or paints.

The finishing, is characterized by the smart mixing of coloured oils, made of plant extracts, that penetrate the wood deeply, colouring thus the wood in seven different shades, that range from white to black, protecting and preserving it against perspiration.

ENVIRONMENTAL MISSION

The relationship between man and wood has been always special. Today, this relationship has passed to another era. Wood consists an essential material for human life, thanks to its capacity to absorb and retain carbon dioxide. By combining this natural property with the low emission rate of pollutants that are generated during its processing and transformation, and by always respecting the management of other materials that are used in the manufacturing process, wood can play a leading role in the battle against climate change.

The management of forests in a sustainable way, allows the forests of the planet to expand, increasing thus the beneficial effects of wood to the environment. Each tree is cut at the peak of its life cycle and is replaced by a sapling which, after growing, will absorb even more carbon dioxide that its predecessor. The hardwood floors continue their beneficial to environment action, even after being installed in a residence. More particularly, they improve the thermal efficiency, balance the humidity of the environment and given the fact that their glues and varnishes are free of toxic solvents, they create the appropriate conditions for a natural and healthy living.

Since the beginning of the previous century, our associated companies manufacture wood products, a process that begins at the heart of a forest. The tradition still goes on until today and has been established, as in the case of the facilities of one of our associated companies (Fontaines in France), where the selection of raw materials takes place with the full compliance with the respective French regulation, achieving thus a sustainable ecological forest management. In France, the laws that regard the protection of wood date back to the 12th century, when wood was the principal raw material for the construction of buildings, as well as in the sectors of shipping and defense. The splendid oak forest of Cîteaux, in the heart of Burgundy, has been planted by Cistercian monks.

The French forestry tradition began in the medieval era and continued with Louis XIV, who established the forest registry, promoting thus the respect, protection and constant regeneration of a huge forestry heritage. The forest management regards a life cycle of 160 years. During this cycle, every tree is numbered and monitored during the different stages of its growth, so that the progressive development of forest areas is ensured.

The old trees that are cut leave behind hundreds of descendants that have already been planted, in constantly expanding facilities. Thanks to the careful forest management during the last century the French forests thrive, doubling their size and tripling their volume.

Through this ancient culture, our associated companies have inherited the knowledge, passion and respect for wood.

CERTIFICATIONS

Alexyl is the exclusive representative of many leading companies with excellent records in the European scene, that are certified with the most important international certifications, which allow us to offer the following guarantees:

The compliance of our products with the most stringent quality standards, that can meet the expectations of the customers.

The increased satisfaction of our customers through the continuous improvement of the overall management system of our company.

A management system of the production processes which is compatible with the most stringent quality standards.

A control of origin and processing of raw materials and of semi-finished products which are used in the manufacturing process of the final products.

A quality system of forest management of the associated companies (exploitation of their own forest areas)

This certification is the formal authorization that is granted by the international institutions that impose the voluntary quality standards for products and services, which certifies at the same time the protection of natural resources and of the environment.

PEFC

This particular certification, that has been granted to many factories we are exclusively cooperating with, and which regards their production facilities, certifies that the raw materials comply with the PEFC (Programme for the Endorsement of Forest Certification) standards.

The application of the regulations that are included in the technical document which is signed by the wood manufacturers of Northern Europe, certifies that a company contributes to the protection of forest ecosystems, by using raw materials that come from forests of Northern Europe, which are managed in an environmentally-friendly way.

The PEFC (Programme for the Endorsement of Forest Certification) is an independent international non-profit organization, having as goal to promote the sustainable management of forests at every level and to contribute to the improvement of the image of wood manufacturers. This goal is achieved thanks to the environmentally-friendly forest management which is certified through the system of traceability of wood products, that “reveals” all their manufacturing stages, from the processing of raw materials to the final stage (the manufacture of products or wooden floors).

Today, according to the assessment of the PEFC, there are more than 46 million hectares of certified forest management worldwide.

SAFETY

Ensuring that the varnish on the floors we sell is safe is our primary obligation. The manufacture process and the materials that are used, so that the floor takes its final form, are accompanied by a very important certification for the protection of the health of everybody.

The watercolour paints and the varnish, which has the property that it does not retain microorganisms that could cause allergies, have the stringent certification that they do not contain formaldehydes. It must be remarked that in order to prove this, it is required to produce the relative certificates, which are kept in our stores, signed by the competent bodies.